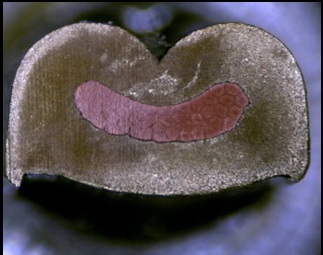

Terminal Crimping Microscope - it generates images showing the cross-sectional view of the terminal crimping. Other than standard tensile force test , it offers another method for us to to evaluate the quality of terminal crimping.

Digital Profile Projector - it measures the dimension of cables, terminals and plastic components in high precision.

X Ray Machine - it facilitates us to check the quality of terminal/ wiring connection without any breakage of the molded plugs and cables.

Flammbility Tester - It helps to evaluate if our plastic material can meet V0, V1, V2, VW-1 FT-1 and HB grade before submitting for safety approval.

Flexing Tester- it can assist us in developing the Stress Relief (SR) that meets the special Flexing test requirement of our clients.

Torsion Tester- it winds the cable by 5 turns in clockwise direction and then by another 5 turns in anti-clockwise direction and the process is repeated continously. It is a special design testing machine used for portable appliances like vacuum cleaner and power tool.

Migration Tester - It ensures the special blended plastic materials not to migrate to the appliance surface.

Aging Tester - Place the cable in tough working environment for Aging test and it is one of the most critical tests in our laboratory. We fulfill the test requirement of UL 758 (hook up wire), UL 62 (power cable) and VDE 0281, HD21, IEC227 (for power cable)

Low temperature winding tester - it winds the cables under an extreme cold temperature to ensure the cables not to be crushed under low temperature environment.